Titanium Abutments

This collection is empty

Our collections

View all

Recently viewed

Introduction:

When it comes to dental restoration, precision and strength are paramount. Titanium abutments from dip offer the ideal solution, combining lightweight design, high strength-to-weight ratio, and exceptional biocompatibility in a single unit. In this comprehensive guide, we delve into the world of titanium abutments, exploring their benefits, applications, and the science behind their success.

The Versatility of Titanium Abutments:

Compatible Titanium Abutments:

dip's titanium abutments are a versatile choice for dental restoration systems. Crafted from titanium nitride-coated Grade 5 Ti-6AL-4V-ELI, these abutments boast superior strength. Each undergoes rigorous fatigue and compression testing to ensure unrivaled quality. With a diverse portfolio offering various widths, collar heights, shapes, and angulations, dip caters to every implant scenario. These abutments are compatible with over 70 of the market's leading implant systems, ensuring versatility and ease of integration.

Advantages of Ti-6AL-4V-ELI and TiN Coating:

The Ti-6AL-4V-ELI alloy enhances titanium's innate properties, creating a material that is lightweight, biocompatible, and corrosion-resistant. The addition of a titanium nitride (TiN) coating strengthens the abutment's surface, improving resistance to wear and abrasion. This coating enhances its interaction with the oral environment and maintains a proper friction coefficient within the implant complex.

Titanium Temporary Abutments:

In addition to standard titanium abutments, dip offers titanium temporary abutments featuring a grooved cuff for improved bonding. These temporary abutments can be customized by cutting them at the groove, allowing for personalized abutment height. During the critical post-osteotomy healing phase, the choice of abutment material significantly influences proper bone and tissue healing. Titanium's mechanical, physical, and biocompatible properties make it an ideal choice for temporary abutments, ensuring optimal healing and implant stability.

The Power of Titanium in Dental Implantology:

Titanium's Aerospace Roots:

Titanium's journey in dental implantology began with its extensive use in the aerospace industry during the 1950s. This lightweight material quickly gained recognition for its remarkable properties. Compared to steel, titanium is 30% stronger and 50% lighter, making it an ideal choice for demanding aerospace applications. It exhibits exceptional resistance to heat, corrosion, and varying temperatures.

Titanium in Modern Implant Dentistry:

Today, titanium is a cornerstone of dental implantology, cherished for the same qualities that endeared it to the aerospace industry. Its high strength-to-weight ratio, low weight, and resistance to corrosion and temperature variations make it the preferred choice. Notably, titanium's exceptional biocompatibility makes it an ideal material for dental restoration.

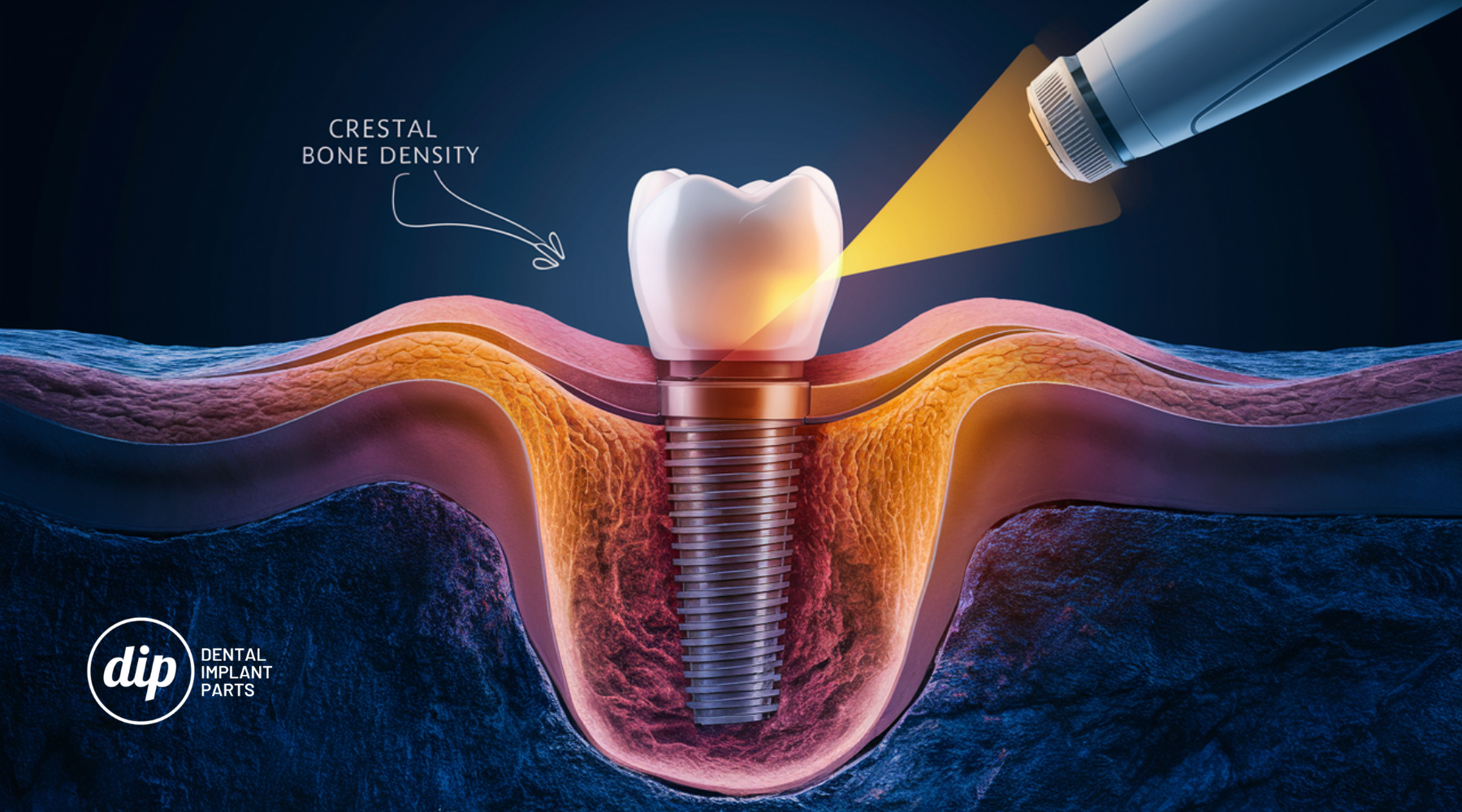

Driving Osseointegration with Titanium:

Osseointegration is a key factor in successful implant therapy. Titanium's high biocompatibility contributes to the initial stages of osseointegration, ensuring proper bone and soft tissue healing around the implant. Moreover, titanium enables long-term benefits by preserving the peri-implant soft tissue barrier, crucial for sealing off the implant site against microleakage.

In conclusion, titanium abutments from dip offer unmatched strength and biocompatibility for dental restoration. Their compatibility with various implant systems, Ti-6AL-4V-ELI alloy, TiN coating, and aerospace-grade origins make them a top choice in modern implant dentistry. Choose dip's titanium abutments for precision, durability, and successful restorations.

#dentalimplantparts #dip #titaniumabutment #dentalabutment